Easy to clean sensor designs and reliable long-term operation make Rheotherm flow meters an excellent choice for many food and beverage applications, especially where sanitary flow meters are required.

Food Additive Flow Monitoring

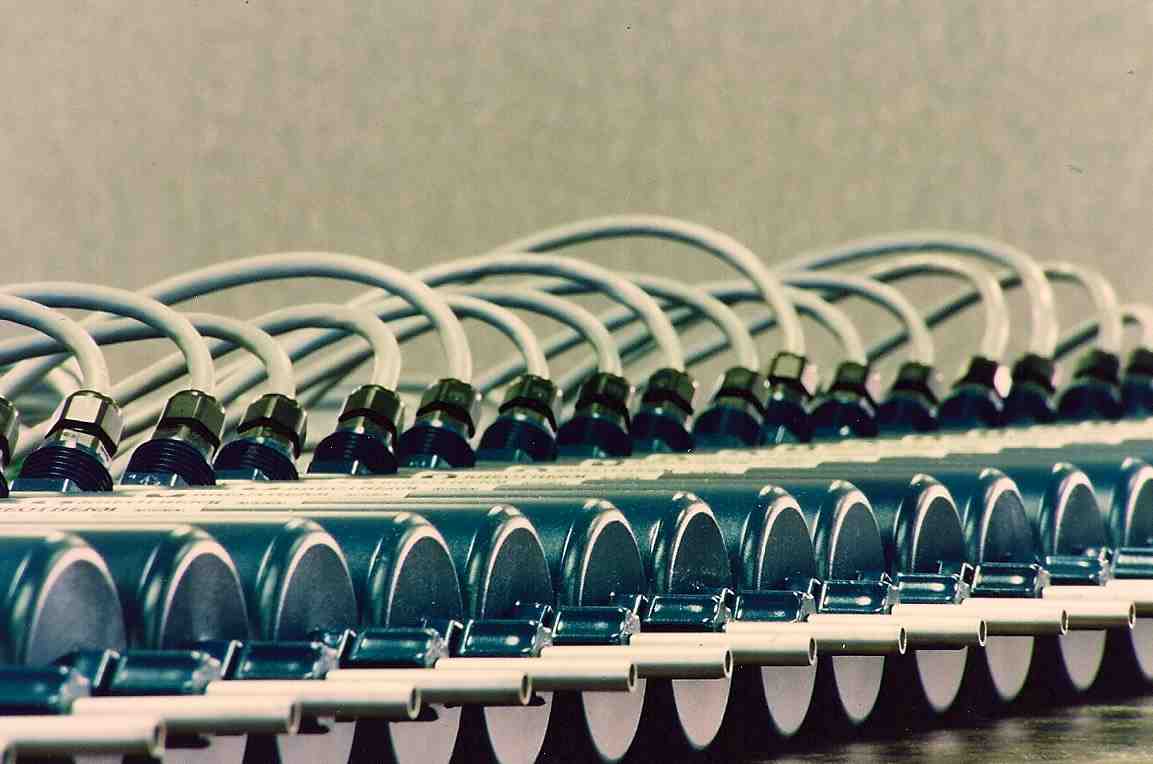

A snack food manufacturer uses over 100 Rheotherm nonintrusive flow switches to monitor the flow of a snack chip food additive. A relay changes state when flow drops below the preset level. With a straight-through flow tube, all wetted material surfaces are simple to clean and sanitize. Sensors with 1/8” flow tubes are used to trip at flow rates as low as 3 cc/min.

A snack food manufacturer uses over 100 Rheotherm nonintrusive flow switches to monitor the flow of a snack chip food additive. A relay changes state when flow drops below the preset level. With a straight-through flow tube, all wetted material surfaces are simple to clean and sanitize. Sensors with 1/8” flow tubes are used to trip at flow rates as low as 3 cc/min.

Rheotherm advantage: easy to clean, no moving parts, high reliability

Click here for details on the Rheotherm flow meter used for this application

Ethanol Flow

For many years, a brewery has used an explosion-proof Rheotherm flow meter to measure the flow of 190 proof ethanol extracted from spent grains. A meter with a 3/8” sensor flow tube is used to monitor flow rates up to 1.8 GPM

Rheotherm advantage: non-contaminating flow tube, accurate low flow measurement

Click here for details on the Rheotherm flow meter used for this application

Oven exhaust

A food manufacturer installed Rheotherm air flow meters in their drying oven exhaust lines. The all stainless steel insertion probes have sanitary process connections for easy installation and removal. The sensors must handle temperatures up to 250°F, and be easily cleaned, since there can be some solids carryover from the product.

Rheotherm advantage: easy to clean, corrosion resistant, low maintenance

Batter Level Switch

A food processing equipment manufacturer uses Rheotherm insertion probe level switches on their batter machine. The accumulation of batter had interfered with the operation of all other level monitoring devices previously tried in that service. Our Rheotherm level switch trips reliably, even with batter build-up on the probes. The stainless steel, no-moving-parts design allows for easy clean up.

Rheotherm advantage: easy to clean, no moving parts, high reliability

Click here for details on the Rheotherm flow meter used for this application