- Low Flow Liquid Meters

- Low Flow Gas Meters

- Duct Flow Meters for Air & Gas

- Low Flow Controller

- MaxExtractor Extraction Monitor

- Multi-Variable Process Meter

- Bidirectional Flow Meters

- RheoVac® Multisensor Flow Monitors

- Flow Switches

- Custom Process Measurement

- Instruments for Hazardous Locations

- Electronics Options

MaxExtractor Extraction Monitor

The Rheotherm® MaxExtractor Extraction Monitor [Patent Pending] is a ground-breaking innovation from Bionetics, your process flow partner. The unique capabilities of this instrument enable you to get the most from your botanical oil extraction process.

The Rheotherm® MaxExtractor is a thermal properties sensor that tracks the changes in the properties of the fluid as the extraction progresses from pure solvent to a solvent with oil extract. Using the MaxExtractor allows you to track the rate of extraction of oil from the plant matter and determine when the extraction process is complete. The MaxExtractor gives you the information needed to fine tune your process and increase your efficiency. Save time. Save money. Improve product throughput with the MaxExtractor.

The Rheotherm® MaxExtractor is a thermal properties sensor that tracks the changes in the properties of the fluid as the extraction progresses from pure solvent to a solvent with oil extract. Using the MaxExtractor allows you to track the rate of extraction of oil from the plant matter and determine when the extraction process is complete. The MaxExtractor gives you the information needed to fine tune your process and increase your efficiency. Save time. Save money. Improve product throughput with the MaxExtractor.

——————————————

What Can We Measure?

The Bionetics Rheotherm MaxExtractor Extraction Monitor can be used to monitor the extraction of oils from botanicals using any of these common extraction techniques:

Ethanol

Ethanol extractions involve a system where ethanol is recirculated through a vessel full of plant matter, or a vessel is filled with ethanol and agitated for a period of time. The resulting ethanol-oil mixture is then filtered to remove sediments and the majority of the ethanol is evaporated off and recovered.

The MaxExtractor is offered with a Class I Div. 1 explosion-proof rating making it the perfect fit for ethanol extraction systems. The MaxExtractor is able to operate in a wide range of ethanol systems and can be adapted to work in both recirculating and washing type extractions. The MaxExtractor can analyze the amount of oil being extracted by the ethanol and alert you when the oil is completely extracted, or the ethanol is saturated.

Hydrocarbon

During a Hydrocarbon extraction, a solvent such as butane, propane, or hexane is poured or sprayed into the top of a vessel filled with plant matter. The liquid solvent and oil mixture is collected from the bottom of the vessel and then the hydrocarbon is evaporated leaving the extracted oil behind.

The MaxExtractor is compatible with a wide variety of hydrocarbon extractions, such as butane, propane, and hexane. The high-pressure rating and explosion-proof FM approval means that the MaxExtractor can measure both liquid and gas phase solvents, allowing you the ability to track the progress of your extraction like never before.

Supercritical CO2

Supercritical CO2 extractions operate at a very high pressure and high temperature to ensure that the CO2 is in a supercritical phase. The CO2 is first passed through a pressure vessel full of plant matter then the solids are filtered out. After leaving the high pressure side, the fluid passes through a pressure reducing orifice and transitions back to a gas phase. When the CO2 becomes a gas, all of the extracted oil falls out of solution and is collected in a tank. The CO2 is then recovered and recompressed for future use.

The high-pressure requirements for supercritical CO2 extraction systems make the MaxExtractor a perfect instrument for measuring extraction progress. The MaxExtractor can be pressure tested for up to 6000 PSI and is compatible with a wide array of flow ranges.

Contact us using the form on this page or any of the ways shown on our Contact Us page to discuss how we can help you optimize your extraction application.

How does it Work?

The Rheotherm MaxExtractor Extraction Monitor is a thermal properties sensor which detects the change in viscosity, thermal conductivity, and heat capacity as the fluid transitions from pure solvent to solvent with oil extract. The output of the instrument is a combination of these three thermal properties and when this output is tracked over time, it provides important information about the rate of extraction, the magnitude of oil extracted and when your extraction is complete so that you can MAXimize the extraction of oil from your plant material in the optimal processing time.

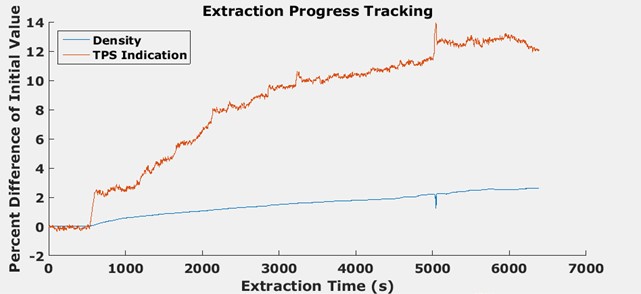

This chart shows the output of the MaxExtractor Extraction Monitor (‘TPS Indication’ in the chart).

The MaxExtractor is zeroed under conditions with no oil in the stream and provides an output-percent deviation from zero which is relative to the amount of oil in the stream. Tracking the magnitude and the rate of change of this output can allow you to determine the magnitude of oil and the extraction rate for your system. Most importantly, the MaxExtractor can tell you when you are no longer extracting oil and you can move on to the next stage of your process.

Many liquid-based extractions use a recirculating type process where an extractor is filled with biomass and solvent, the solvent is drained out from the bottom and pumped back over the top. In these extraction setups, the MaxExtractor is installed in the recirculating line to determine the amount of extracted oil in the flow stream out of the extraction vessel.

Other extraction methods can operate with a washing or centrifuge type process where the extractor is filled with biomass and solvent and the biomass is spun or agitated in the solvent pool. In these cases the MaxExtractor is located in a small bypass line where a small amount of fluid is continuously sampled and pushed through the sensor to determine the amount of oil. This same setup can be used for recirculating processes if the recirculation pump does not have a steady flow rate.

Most hydrocarbon and supercritical CO2 extractions use a once-through operating principle, where fresh solvent is pushed through the extractor until all oil is extracted. The MaxExtractor can improve the efficiency of these operations by detecting the rate of oil extraction. In these systems, two MaxExtractor Extraction Monitors are used, one before and one after the extractor. The output of the two sensors are compared and the difference between them is proportional to the instantaneous concentration of extracted oil.

How Are They Installed?

The Rheotherm MaxExtractor Extraction Monitor incorporates an in-line Rheotherm sensor that is installed with a variety of fittings options including sanitary, NPT, and Swagelok compression fittings. Contact us to discuss your specific process requirements.

How Do I Get One?

Contact one of our extraction application specialists using the form on this page to configure an instrument tailored to your needs. You can also visit our Contact Us page for telephone, fax and email information.

- Output of solvent vs. extract concentration

- Advanced temperature compensation

- Measurement of liquids or gases

- Exclusive inline TU sensor

- Advanced signal processing electronics

- Easy installation

- Long-term reliability

| Temperature | Process: 0 – 120°F (-18 – 50°C) Environment: 0 – 120°F (-18 – 50°C) |

| Pressure | 0 – 500 PSI |

| Calibration Ranges | 10:1 Turndown (standard) Up to 100:1 Turndown available Liquids: 0.05 cc/min to 2 LPM Gases: 0.0017 to 3 SCFM |

| Calibration Accuracy | ± 1% of reading typical |

| Response Time | 1 sec. ; 3 – 5 sec. typ. (63% of range) |

| Repeatability | ± 0.5% of reading |

| Line Sizes (flow range dependent) |

1/16”; 1/8”; 3/16”; 1/4” |

| Process Connection | Plain tube stubs suitable for compression fittings |

| Wetted Material | 316 SS |

| Display | 2-line OLED display of: – Mass/volume flow rate – Setpoint |

| Enclosure | Sensor: PVC Integrated Electronics: NEMA 4X Cast Aluminum |

| Flow Output | 4 – 20 mA (standard); 0 – 10 or 0 – 5 VDC (optional) |

| Input Power | 24 VDC ±4V @325 mA (max) |

|

|

||||

|

|