Condenser Pressure and Air In-Leakage

Surface condensers, in the form of large shell and tube heat exchangers, are used in power generation to condense the steam used in the process back into water. Cooling water flows through tubes surrounded by an air-tight shell creating a sub-atmospheric pressure vacuum-tight space where the steam exhausted from the turbine generator condenses. If air and other non-condensable gases (collectively referred to as ‘air in-leakage’) are not effectively removed from the steam space, it can impede heat transfer and upset water chemistry within the condenser. Other problems arising from air in-leakage include:

- Excess turbine backpressure

- High dissolved oxygen

- Corrosion or ammonia grooving

- Increased plant heat rate

Condenser air in-leakage must be kept below the capacity of the exhausters because condenser pressure increases when air in-leakage exceeds the capacity of the air removal system. As the design limitations of the air removal system are surpassed, additional exhauster capacity must be placed in operation or the condenser pressure will increase.

When exhauster capacity is exceeded, condenser pressure is dictated by the performance curve of the exhausters based on inlet pressure to the exhausters rather than the condenser’s performance curve based on cooling water inlet temperature. Considering that a slight increase in backpressure can result in hundreds of thousands of dollars in extra operational costs annually, costs for inspection to determine the source of air in-leaks may be recovered immediately.

Condenser Air In-Leak Survey

Helium leak detection often results in a guessing game of ambiguous conclusions requiring trial and error outage fixes to verify. Continuous air in-leak monitoring has been used effectively by Intek to augment helium leak detection by providing quantification of leaks that are identified during the testing. Quantifiable air in-leak surveys are performed using Helium leak detection in conjunction with RheoVac condenser monitoring technology.

A ball valve fitting installed in the air extraction line between the condenser and vacuum system allows a RheoVac condenser air in-leak probe to be installed facilitating temporary or permanent monitoring of air in-leak and exhauster capacity for steam jet air ejectors or liquid ring vacuum pumps. To learn more about the RheoVac Air In-Leak monitor probe, click here.

A condenser air in-leakage survey facilitates:

- Routine inspections to maintain an efficiently operating condenser.

- Verification prior to an outage so components in need of repair are addressed and after the outage to ensure all repairs were made successfully.

- Emergency inspections where the unit is unable to maintain maximum efficiency.

How Does it Work?

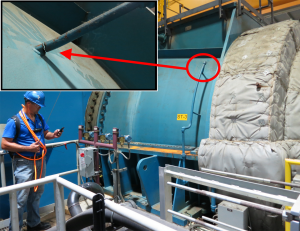

The inspection begins on the turbine deck, working from top to bottom at all areas within the vacuum boundary. This includes valves, flanges, rupture diaphragms, pump seals and any other components under vacuum. Helium is applied to the various components within the vacuum boundary of a Turbine and/or Condenser system. A leaking component will allow the helium to enter the steam space and from there, the helium will be removed by the unit’s air removal system. A spectrometer located at the discharge  of the air removal system registers an indication and the source of the leak is recorded. A suspected leak is then temporarily sealed, if possible, and the change is immediately quantified by the RheoVac instrument.

of the air removal system registers an indication and the source of the leak is recorded. A suspected leak is then temporarily sealed, if possible, and the change is immediately quantified by the RheoVac instrument.

Our condenser air in-leak survey will include the severity of the leak(s), the location of the leak(s), and potential repair options. The Intek Engineers performing the test pay strict attention to all details during the process in order to provide you the most thorough results possible. The survey will provide confidence and understanding of the steps needed to address the air in-leakage problems. The RheoVac instrument may be left at the site to allow plant personnel to validate repairs.

Want to Learn More?

If you believe that your plant performance is being impacted by excess air in-leakage, let Intek show you how you can quantify the problem and mitigate the problem. Contact us using the form on this page or calling us at the number at the top of the page. You can also go to our Contact Us page for more ways to reach us.