Condenser Pressure and Temperature Instruments

A recognized common problem with results from most condenser performance assessments is the accuracy of condenser shell side pressure measurement. While pressure transducers are well understood and typically provide reliable measurement at the sensing location, plants commonly connect the transducer to the condenser on the turbine deck. This often requires long runs of connection lines where standing water has been found to introduce a significant pressure differential leading to inaccurate measurements.

Any error in these critical measurements may lead to incorrect assessment of condenser performance which can result in significant, and many times unnecessary, losses in output and increased costs.

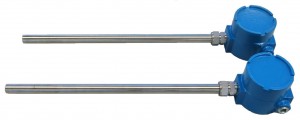

Bionetics Pressure and Temperature Probe

Bionetics Pressure and Temperature (PT) probes allow theses two measurements to be made within the steam space providing a more accurate determination of actual condenser pressure. The integrated temperature sensor of the PT probe is used to verify the correctness of these two independent measurements. The instrument is installed through a ball valve assembly, which accommodates easy online maneuverability.

Bionetics Pressure and Temperature (PT) probes allow theses two measurements to be made within the steam space providing a more accurate determination of actual condenser pressure. The integrated temperature sensor of the PT probe is used to verify the correctness of these two independent measurements. The instrument is installed through a ball valve assembly, which accommodates easy online maneuverability.

These instruments are designed for long-term, reliable use in steam surface condenser performance monitoring applications, new condenser commission testing and short-term condenser performance evaluations.

High Density Temperature Array Instruments

In order to better understand the impact of air binding and storage within the tube bundle, Bionetics has developed a unique temperature sensor. The Submersible High Density Temperature Array is an array of RTDs designed to be installed across several tubes in the outlet tube sheet. The information gathered from this instrument enables creation of thermal profiles of cooling water outlet temperature and is also used to monitor air (and other non-condensable gas) binding. This data provides critical information for upgrading condenser bundle performance via internal bundle modifications which can improve heat rate, increase air in-leak immunity, reduce DO and other chemistry-related issues.

In order to better understand the impact of air binding and storage within the tube bundle, Bionetics has developed a unique temperature sensor. The Submersible High Density Temperature Array is an array of RTDs designed to be installed across several tubes in the outlet tube sheet. The information gathered from this instrument enables creation of thermal profiles of cooling water outlet temperature and is also used to monitor air (and other non-condensable gas) binding. This data provides critical information for upgrading condenser bundle performance via internal bundle modifications which can improve heat rate, increase air in-leak immunity, reduce DO and other chemistry-related issues.

A key feature of these instruments is that they are specifically manufactured and calibrated to implement ASME PTC 12.2 Performance Tests.

Additional Temperature and Pressure Instruments

In addition to several available Bionetics-designed condenser instruments, a number of other test-grade instruments are used to measure the key parameters needed to fully understand the performance of your condenser. The high quality measurements provided by these instruments help to correctly identify the problem areas within the condenser and related systems (vacuum equipment, circulating water) and enable the impact of the issues to be quantified along with identification of potential areas for improvement. Some of the other instrumentation used includes:

In addition to several available Bionetics-designed condenser instruments, a number of other test-grade instruments are used to measure the key parameters needed to fully understand the performance of your condenser. The high quality measurements provided by these instruments help to correctly identify the problem areas within the condenser and related systems (vacuum equipment, circulating water) and enable the impact of the issues to be quantified along with identification of potential areas for improvement. Some of the other instrumentation used includes:

Test grade RTD sensors are used to measure circulating water inlet, average intermediate and average outlet temperatures.

Test grade RTD sensors are used to measure circulating water inlet, average intermediate and average outlet temperatures.- Test grade differential pressure sensors used to determine total condenser flow and differential pressure.